Construction, RC Frame, Structural

Casting Concrete for Vertical Elements — The Professional Method

1) Scope & Purpose

This procedure covers the full cycle for double-shutter vertical elements (columns and walls): preparation, fixing, inspection, concreting, finishing, striking, and quality control—so the works meet drawings, specifications, and codes. (See Scope/Purpose, pp. 3–4.)

2) Resources: Materials, Plant & People

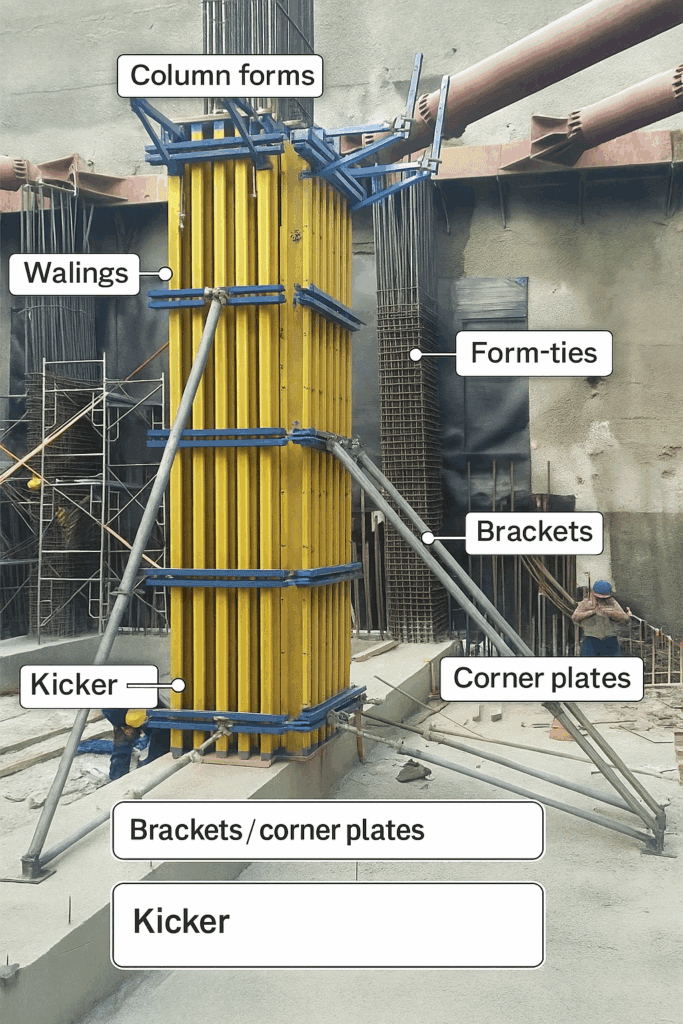

- Materials: approved rebar, spacers/cover blocks, shutter release agent, form ties, Bartec couplers.

- Plant & Equipment: concrete pump/tower crane, vibrators, levelling tools, waling systems, brackets and working platforms. (p.4)

- Personnel: PM, construction/MEP managers, QA/QC, Site Engineer, carpenters, steel fixers, scaffolders, concrete crew. (p.4)

3) Safety & Site Set-Out

Toolbox talks, barriered access, lighting, and welfare are mandatory. After the raft/slab is cast and released, mark grid lines, wall/column axes, and levels; check formwork against latest approved drawings before Work Inspection Requests (WIR). (pp.5–6)

4) Kickers (Starter Stubs)

Form kickers on the slab to give a clean, plumb start line and a bond-key for the next pour. While the kicker concrete is still green, apply a surface retarder to expose fines; if hardened, lightly scabble to provide a key. Keep kickers cureduntil the next pour. (pp.5–7)

5) Reinforcement Fixing

Fix and tie rebar to drawings; maintain cover with approved spacers; clean rust, oil, and laitance; keep laps/couplers where shown. Install rings/ties and maintain bar cleanliness and spacing for vibration paths. (p.7)

6) MEP Openings & Embedments

Coordinate sleeves, boxes, and anchors before closing shutters. All MEP works are surveyed and approved, with positions matching drawings to avoid clashes or displacements during pour and vibration. (p.8)

7) Formwork Erection & Bracing

Close shutters after final cleaning and release‐agent application. Use approved systems with walings, ties, and brackets; seal joints to prevent grout loss. Figures show typical column formwork, corner plates/brackets, and rectangular/circular arrangements, including recommended tie angles for rectangular sections to maintain plumb. (Figures 1–7, pp.9–14)

Ensure safe working platforms and guard-rails as detailed, with permits and load ratings (e.g., 1.5 kN/m² platforms; see Figs. 9–10, pp.19–20).

8) Pre-Pour Checks & WIR

Submit a WIR at least 24 hours before placing concrete. Joint checks by Site Engineer, Foreman, and QA/QC confirm: alignment, dimensions, tie tightness, joint sealing, embedment positions, access for pour/vibration, and platform integrity. (pp.17–18)

9) Concrete Placing, Vibration & Finishing

- Organise pump access, standby vibrator, and concrete delivery logistics.

- Place in controlled lifts; avoid free-fall > 1.5 m; use internal vibrators correctly (no contact with rebar/formwork).

- Maintain continuous pour to avoid cold joints; compact each layer fully before the next.

- Protect against hot/windy conditions to reduce plastic shrinkage and temperature rise; finish to specified surface class. (p.21)

10) Striking the Formwork

Observe project-specific striking times. Sequence: remove loose items, then release opposite shutters while leaving sufficient forms/ties to keep the element stable; never use a crane to break cohesion—use timber wedges/pry bar. (p.22)

11) Curing & Early Repairs

Immediately after striking, apply curing compound or wet hessian and keep moist per spec. Identify any defects (blowholes, honeycombing) with QA/QC and repair as approved. (p.23)

12) Quality Control: Tolerances, Inspections & Testing

- Dimensional tolerances (examples): section ±5 mm (≤400 mm) / ±10 mm (>600 mm), position ±10 mm, verticality h/500, opening size ±5 mm. (p.24)

- Inspections cover rebar, embedments, formwork, access/platforms, release agent, and trial lifts where required.

- Sampling & Testing: make and cure cubes to BS EN 12390; typical rate per spec (e.g., at least 1 set per 25 m³), with additional durability tests (chloride/RCPT) if specified. (p.25)

Pro Tips from the Method Statement

- Plan tie layouts to suit rebar congestion; keep vibrator paths open (see rectangular column tie angles, Fig. 5, p.12).

- Brace against wind and ensure safe crane re-setting; follow max sling angles and lifting bracket guidelines (p.16).

- Seal joints meticulously to prevent grout loss and blow-outs; check with light pressure-wash pre-pour (p.17).

Why This Matters

Getting vertical elements right avoids rework, ensures alignment for follow-on trades (façade, partitions, MEP), and locks in structural performance. With disciplined WIRs, tolerances, and testing, you deliver repeatable quality on every pour.