Uncategorized

Key Factors to Consider When Designing with Structural Steel Design

Structural Steel Design Considerations

Structural Steel Design offers numerous advantages, from its high strength-to-weight ratio to its versatility in architectural applications. However, harnessing these benefits requires a thorough understanding of the key factors that influence the design process.

In this comprehensive guide, we’ll explore the essential considerations to keep in mind when designing with structural steel to ensure optimal performance, safety, and cost-effectiveness in your construction projects.

Material Selection

Types of Structural Steel Design:

Different grades and types of Structural Steel Design are available, each with unique properties and characteristics. Common types include ASTM A36, ASTM A572, and ASTM A992. The choice of steel grade depends on factors such as the required strength, toughness, and corrosion resistance for your specific application.

Coating and Finishes:

Steel can be treated with various coatings and finishes to enhance its durability and resistance to corrosion. Options include galvanizing, painting, and powder coating. The selection of the appropriate coating depends on the environmental conditions the steel will be exposed to, such as humidity, saltwater exposure, and chemical exposure.

Structural Analysis and Design

Load Analysis:

Accurate load analysis is crucial for determining the required size and configuration of steel members. Dead loads (the weight of the structure itself) and live loads (occupant loads, furniture, and equipment) must be carefully calculated and considered in the design process.

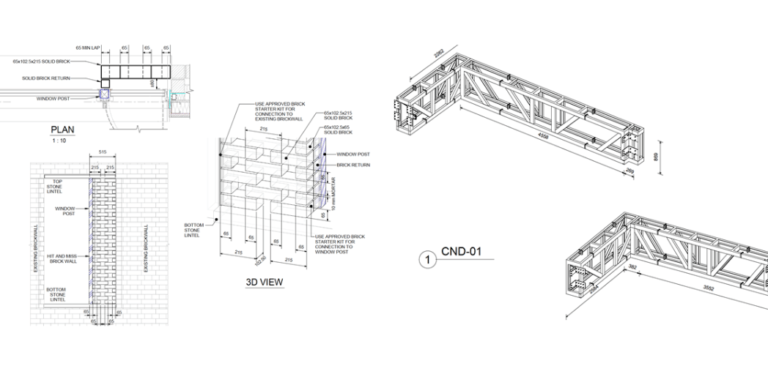

Connection Design:

The design of connections between steel members is a critical aspect of structural steel design. Properly designed connections ensure the stability and integrity of the structure under various loading conditions, including wind, seismic activity, and thermal expansion.

Aesthetic and Architectural Considerations

Architectural Flexibility:

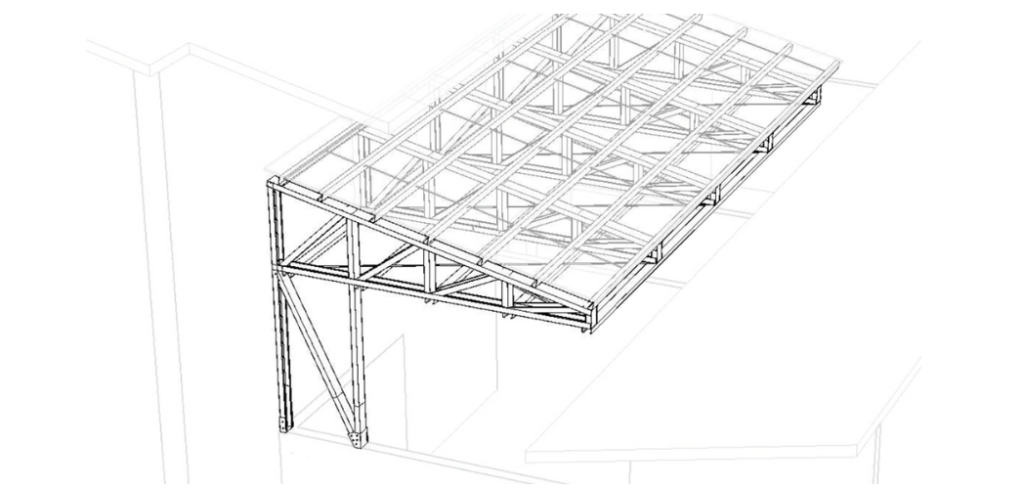

Structural steel offers unparalleled architectural flexibility, allowing for innovative and creative design solutions. The use of steel in architectural applications can result in open and expansive interior spaces, sleek and modern aesthetics, and unique structural forms that may be unattainable with other materials.

Exposed vs. Hidden Steel:

The decision to expose or hide structural steel elements can significantly impact the design and aesthetics of a building. Exposed steel beams and columns can create a bold and industrial look, while hidden steel elements can provide structural support without compromising the overall design aesthetic.

Fabrication and Construction

Prefabrication vs. On-Site Fabrication:

Prefabricated steel components can accelerate the construction process and improve the quality and consistency of the finished product. However, on-site fabrication may be necessary for custom or complex designs that cannot be achieved with prefabricated components.

Quality Control and Inspection:

Ensuring the quality of fabricated steel components is crucial for the structural integrity and performance of the finished structure. Regular inspections and quality control measures should be implemented throughout the fabrication and construction process to identify and rectify any potential issues or defects.

Environmental and Sustainability Factors

Recyclability:

Steel is one of the most recyclable materials, with a high recycling rate that contributes to its sustainability and environmental friendliness. Utilizing recycled steel in construction projects can reduce the environmental impact and carbon footprint associated with steel production.

Energy Efficiency:

The thermal properties of steel can influence the energy efficiency of a building. Proper insulation and design considerations can optimize the thermal performance of steel structures, reducing heating and cooling costs and enhancing occupant comfort.

Cost Considerations

Initial Costs vs. Lifecycle Costs:

While the initial cost of Structural Steel Design may be higher than some alternative materials, its long-term durability and low maintenance requirements can result in significant cost savings over the lifecycle of the building. Evaluating the total cost of ownership, including maintenance, repair, and replacement costs, can help justify the initial investment in structural steel.

Conclusion

Structural steel design offers numerous benefits, but it also requires careful consideration of various factors to ensure optimal performance, safety, and cost-effectiveness. From material selection and structural analysis to architectural considerations and environmental factors, each aspect plays a crucial role in the successful design and implementation of steel structures. By taking a comprehensive and informed approach to design, architects, engineers, and construction professionals can unlock the full potential of Structural steel design, creating innovative, durable, and sustainable buildings that stand the test of time.