Construction, Residential Groundworks

Stormwater Network Installation: London Method, Testing & Inlets

Managing roof and surface runoff is critical on tight London plots. Below is how we install stormwater (surface water) networks—from survey and trenching to inlets, manholes, testing, and reinstatement—so you pass Building Control smoothly and avoid future flooding.

What we install (typical scope)

- uPVC/VC or concrete pipes sized for rainfall design (e.g., 150–315 mm), manholes/chambers, road gully inlets, warning tape, and concrete surrounds at crossings where required.

Our delivery sequence (field-tested)

- Pre-start survey & approvals

Approve shop drawings and permits; set out at ~10 m intervals; open trial pits to locate live services. - Traffic & safety

Implement barriers/signage; provide trench support where needed. - Excavate & protect services

Excavate to formation and trench width; protect any exposed utilities and keep them operational. - Bedding & levels

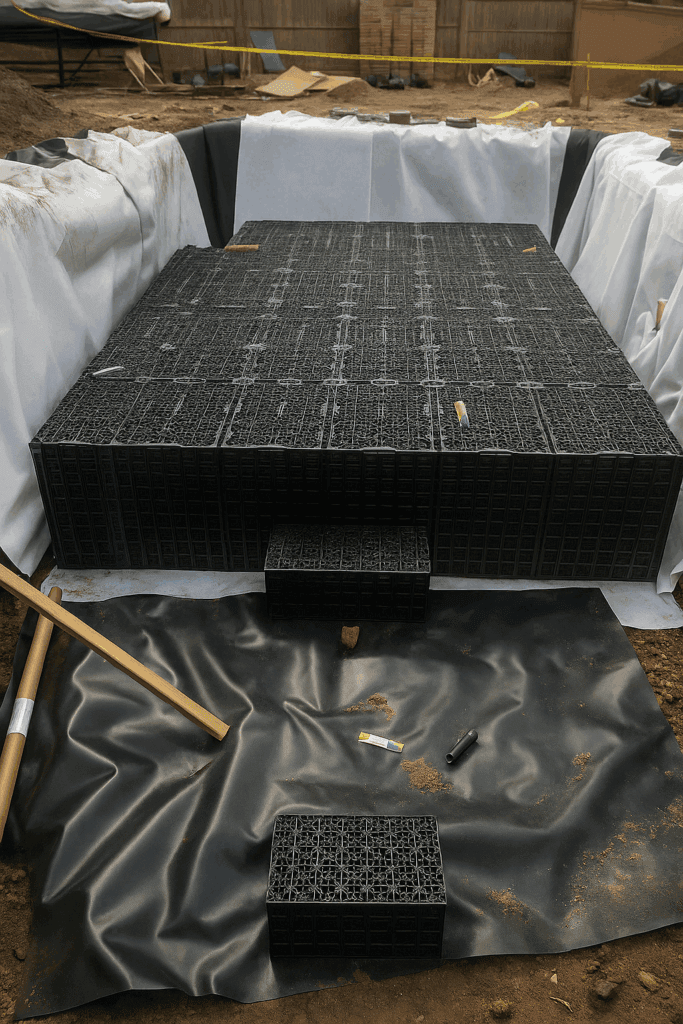

Prepare pipe bedding; confirm gradients with survey kit; compaction test the formation before laying. - Manholes & chambers

Seat bases on 100 mm blinding; stack rings/plastic chambers plumb and watertight; waterproof internal/external faces as specified; submit inspection forms. - Pipe laying (upgrade)

Lay from downstream to upstream to maintain falls; check alignment with rope/mirror methods before final surround. - Hydraulic/watertightness testing

Plug ends, provide a vertical standpipe (≥1.0 m above manhole crown), fill and hold (min. ~1 hr) with joints exposed; test steep runs with a rolling ball. - Backfill & compaction

Surround/backfill in 300 mm layers to ~95% Standard Proctor; place warning tape ~500 mm above mains; use concrete surrounds at road crossings where required. - Gullies/inlets & connections

Set inlets on 100 mm blinding; connect to nearest MH; core-drill tie-ins to existing structures; clean pipelines before handover; install indicator posts where required. - Handover & reinstatement

Plug open ends at day’s end; reinstate to sub-grade for successor trades; compile QA pack (survey levels, test records, inspections).

Why clients pick AmtaarGC

- Tight-site runoff control: storm inlets, pipe falls, and trench support delivered without disrupting neighbours or traffic.

- Inspector-ready QA: water tests, alignment checks, and compaction results documented to chainage.

- One team, end-to-end: from setting out and cores to reinstatement and handover packs.