Substructure

Pile Head Treatment: Step-by-Step Guide (with On-Site Checks)

What is pile head treatment—and why it matters

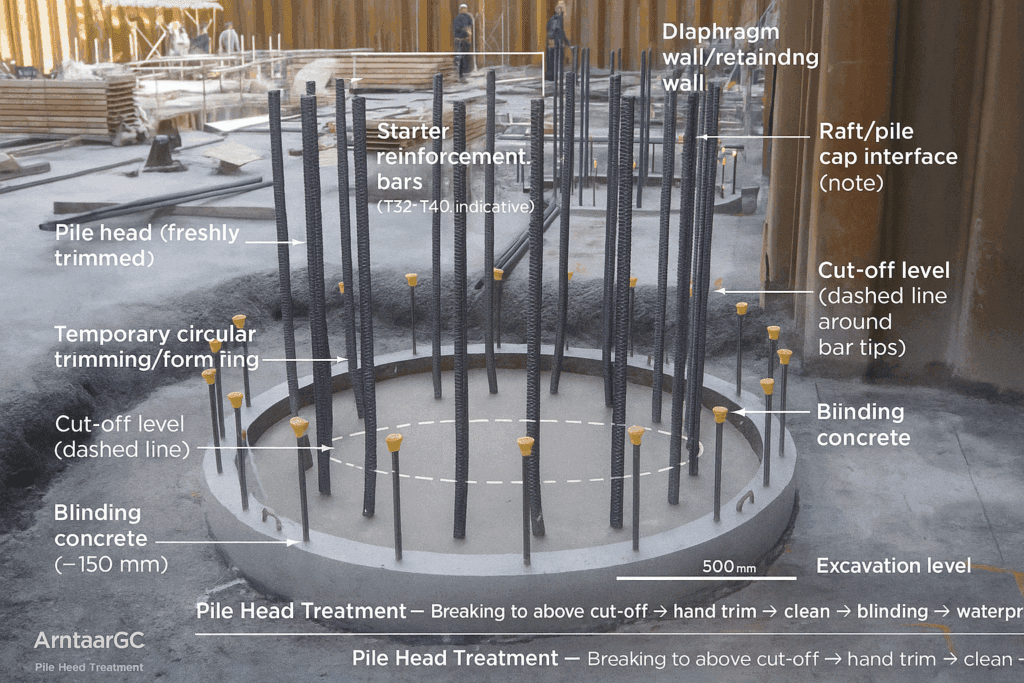

Pile head treatment prepares the top of each pile to bond cleanly with the blinding/raft and to transfer load without slip or weak laitance, while ensuring a watertight interface. A typical method statement sequences dewatering, safe exposure, accurate cut-off, controlled breaking, hand trimming for the final 200–300 mm, reinforcement protection, QA inspections, integrity testing, blinding, and finally pile head waterproofing before raft pour.

The method (contractor sequence)

- Dewater & protect instrumentation

Keep the excavation dry; maintain groundwater at least 1 m below formation and barricade all monitoring instruments (piezometers, extensometers, strain gauges) to prevent damage. If any are hit, notify the Engineer and reinstate. - Expose piles & mark the cut-off

Excavate and clean around piles. Grind a 5 cm guide groove at the design cut-off level and obtain the Engineer’s approval before breaking. - Primary break (hydraulic)

Use a hydraulic pile breaker (e.g., TAETS Type 380) to crush down to just above cut-off, then stop:

- Tension piles (~Ø750 mm): break to 20–25 cm above the cut-off.

- Compression piles (~Ø1500 mm): break to 30 cm above the cut-off.

- Final trim (hand tools)

Complete the last 20–30 cm using hand tools/jack-hammers to avoid spalling at the cut-off edge and to achieve a sound, level bearing surface. Do not damage main bars. - Reinforcement protection & extensions

If any bars are accidentally cut/damaged, extend using splice-type couplers (mandatory for tension piles; as needed for compression piles). Keep steel clean and protected from corrosion. - QA inspections & integrity testing

Clear debris to approved tip, offer for Engineer inspection, and carry out low-strain integrity tests where required. Non-compliances trigger agreed corrective actions before blinding. - Blinding concrete

Place ~150 mm blinding at formation (per approved blinding method), cure with wet hessian and polythene. - Pile head waterproofing & diaphragm-wall interface

Apply the approved pile-head treatment/waterproofing system and coordinate details at the raft/retaining wall interface per separate method statements.

The diagram on page 11 of the method statement illustrates both Case 1 (tension piles) and Case 2 (compression piles), showing the staged crushing (to above cut-off), hand-trimming, and 150 mm blinding around the pile head. Refer to Spot Detail A for the finished interface at the cut-off.

Safety essentials

- Mandatory PPE (head, eye, hand, foot protection).

- Dust suppression (water spray) during breaking.

- Continuous safety oversight by the section engineer and safety officer.

QA/QC you can copy to site

- Use a check sheet & ITP covering: instrument protection, exposure/cleaning, marking & approval, hydraulic break limits, final trim, bar condition/couplers, debris disposal, integrity testing, and witness/hold points for the Engineer. The method statement provides both a Check Sheet and an Inspection Test Plan template.

Common pitfalls (and how this method avoids them)

- Over-breaking at the cut-off: avoided by stopping the breaker 20–30 cm early and finishing by hand.

- Damaged main bars: controlled with marked limits, careful hand trimming, and coupler remediation if needed.

- Poor bond/laitance at interface: removed by controlled trimming and cleaning before blinding and waterproofing.