Cladding, Structural

Understanding Thermal Transfer in Modern Cladding Systems

The SCHÜCO System BB1 Approach

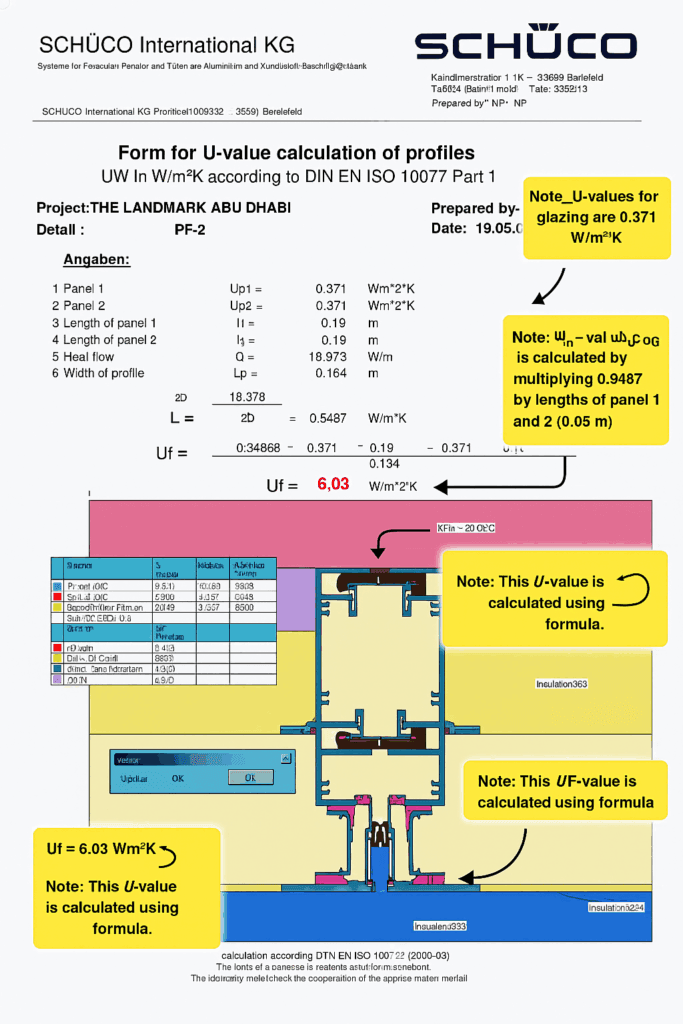

The document prepared by SCHÜCO International KG for the Landmark Tower Project includes detailed U-value forms, isothermal diagrams, and temperature line simulations (pages 15–28). Each façade element—mullion, transom, and panel—was assessed under controlled boundary conditions to map how heat travels through the structure.

According to the results:

- The overall thermal transmittance coefficient of the system was 2.38 W/m²K, balancing glass, frame, and spacer performance.

- Frame thermal transmittance values (Uf) varied between 6.03 and 8.08 W/m²K, depending on profile depth and configuration.

- The edge seal heat loss (Ψ-value) was revised from 0.08 to 0.11 W/mK, following reviewer recommendations to meet EN 13947:2005 requirements.

Visualizing Heat Movement – Isotherm & Temperature Lines

The isotherm plots on pages 17–22 illustrate how temperature gradients distribute across aluminium and insulated glass layers. At an indoor temperature of 22°C and outdoor –5°C, the simulations highlight areas of potential condensation and energy leakage. For example:

- Transom RG-4 showed condensation risk zones near the glass edge, requiring spacer optimization.

- Mullion PF-1 demonstrated a stable temperature field due to improved thermal breaks and gasket positioning.

These visual insights guide designers to refine spacer widths, gaskets, and material interfaces to maintain consistent thermal barriers throughout the façade assembly.

Engineering Significance

For façade contractors and design engineers, SCHÜCO’s method sets a reference standard. It combines:

- Precise EN-based modelling (DIN EN ISO 10077)

- Real project calibration against construction geometry

- Feedback integration between consultants (EPP AG, EC Harris, and ALICO)

Such rigorous validation ensures that façade systems meet not only aesthetic goals but also energy performance benchmarks, reducing building cooling loads—particularly crucial in hot climates like the UAE.

Conclusion

The SCHÜCO System BB1 case study proves that thermal performance is not an afterthought—it’s engineered through testing, simulation, and collaboration. For London and UK façade engineers adopting high-performance glazing systems, this methodology offers valuable lessons in compliance, energy savings, and comfort optimization.

Recommended for Further Reading

- EN ISO 10077-1: Thermal performance of windows, doors, and shutters

- EN 13947:2005: Calculation of linear thermal transmittance for glass edge seals

- SCHÜCO International KG: Sustainable façade design principles